In questi giorni il team di bioingegneri composto da Arti Ahluwalia, Carmelo De Maria e Chiara Belmonte si trova a Nairobi per tenere un corso intensivo nell'ambito del progetto Afra Moya, di cui il...

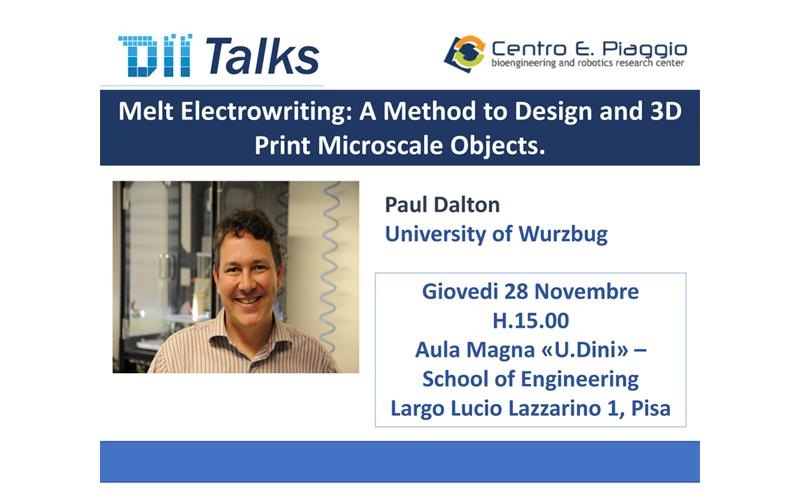

Leggi tutto[DII Talks] Melt Electrowriting: A Method to Design and 3D - Print Microscale Objects

Paul Dalton

University of Wurzbug

Aula Magna «U.Dini» – School of Engineering

Abstract

This lecture will describe the development of melt electrospinning into a distinct class of 3D printing, termed melt electrowriting (MEW). Furthermore, when coupled with intuitive software interfaces and scale up systems, MEW will lead to an extensively used approach that permits both fundamental polymer processing and clinically translational research to be performed in university settings. The ability to alter the diameter on demand provides another set of design variables, and the direct writing of medical fibres builds on many decades of melt processing for medical devices from the regulatory perspective. The benefit for the biomaterials and TERM community is a robust, reproducible and low-cost manufacturing technology that will be widely used over the next decade.

Bio

Paul Dalton is a Professor at the University of Würzburg, Germany with over 20 years’ of interdisciplinary experience with biomedical materials, including polymer processing, surgery, nanotechnology and hydrogels. This interdisciplinary background has been achieved at numerous institutions, including Lions Eye Institute (Australia), University of Toronto (Canada), RWTH Aachen (Germany), University of Southampton (UK) and Jiao Tong University (China). He commenced work on melt electrospinning in 2003, and developed this as a direct-writing technology with Professor Dietmar W. Hutmacher at QUT from 2009. MEW is a distinct class of additive manufacturing with particularly utility for the manufacture of biomedical materials.

| Allegato | Dimensione |

|---|---|

| 1.23 MB |